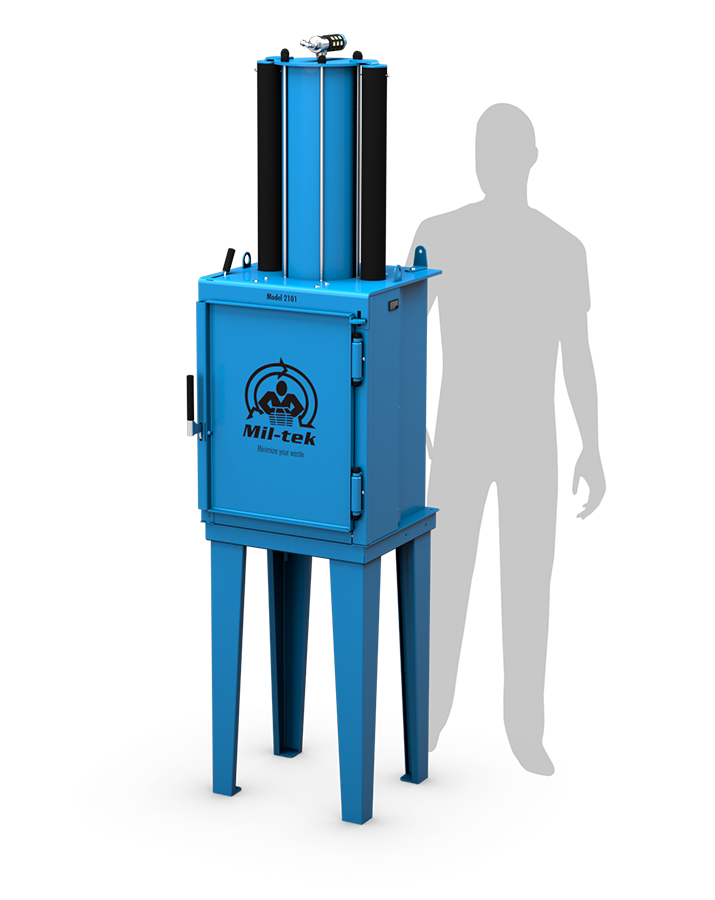

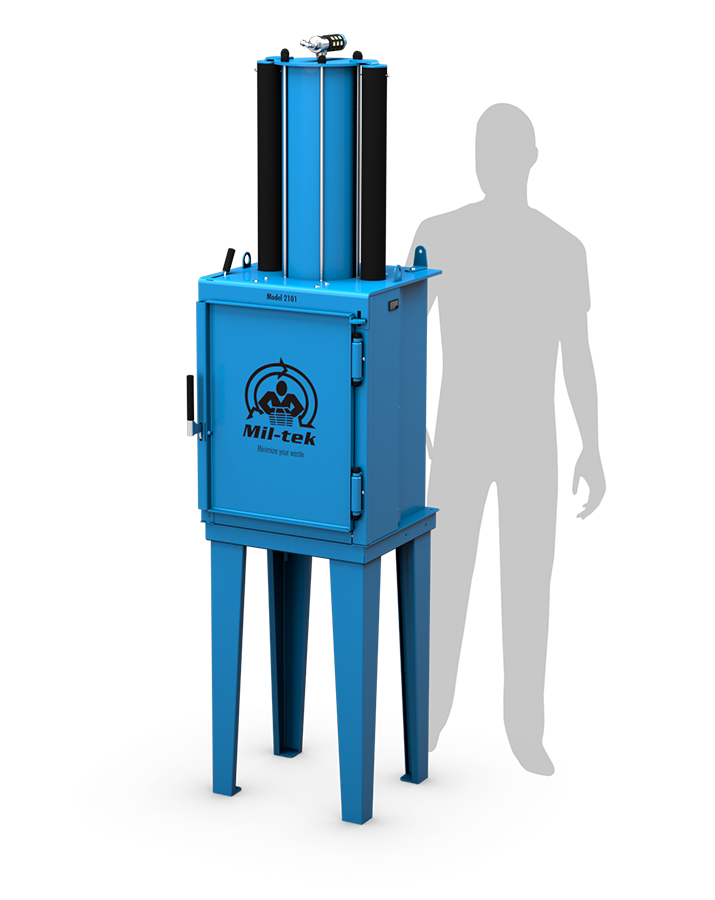

2101 Mil-tek Pneumatic Can Press

-

Crush tins, cans, and drums up to 30 liters

-

Hazardous and non-hazardous fluids

-

Low on noise, low on energy

-

Up to 90% compaction

-

28cm² floor footprint

-

Improved operational and safety features

A Mil-tek 2101 Can Press will reduce the volume of empty cans by 90% and can run from an existing air-line or a supplied compressor, reducing running costs and improving energy consumption.

The Mil-tek 2101 Can Press compacts cans and tins up to 30 liters in size, reducing volume by up to 90%.

Containing no electrical parts, the small-size, heavy-duty Mil-tek 2101 Can Press is both easy to maintain and easy to clean. It can compact metal, steel, tin, and aluminum – almost any form of non-aerosol cans, up to 30L in size.

Whether in food production or manufacturing, many tins and cans contain a waste liquid such as oil, paint, or water, the disposal of which can be both messy and expensive.

The Mil-tek 2101 Can Press reduces the volume of cans and tins by up to 90%, allowing you to reduce the number of waste bins, reduce the number of lifts required and, most importantly, reduce the cost of waste disposal by up to 80%.

The Mil-tek 2101 Can Press is powered by compressed air, either directly from an existing air line or from a compressor supplied by Mil-tek. This means that the Can Press is free of both electrical and hydraulic components, minimizing the risk of fire and completely eliminating the risk of oil contamination.

Capacity

Pressure

Pressing Cycle

< 30 L

2250 kg at 8 bar

10-20 sec.

Height

490 mm

Width

405 mm

Depth

400 mm

Height

2005 mm

Width

525 mm

Depth

510 mm

Noise Level

< 70 db (A)

Approvals

CE

Machine Weight

125 kg

Mil-tek 2101 Can Crusher

Let us help you to find the answers to how your business can save time, space and money by handling your waste more efficiently.

Fill out the form and one of our local representatives will reach out to help.